技术立业丨利元亨半导体玻璃激光穿孔设备,引领未来电子封装技术

随着5G通信、人工智能等前沿科技的迅猛发展,电子产品的高性能需求日益增加,推动了先进封装技术的不断演进。其中,微孔玻璃基板技术——TGV(Through Glass Via)作为一项关键技术创新,在现代电子和半导体行业中展现出巨大的市场应用潜力。特别是在AI算力封装、射频、光通讯及Mini/Micro LED等前沿领域,TGV技术以其独特的高频电学特性、成本效益、简化的工艺流程和卓越的机械稳定性,成为了实现电子产品小型化、轻量化、多功能化的关键途径。

TGV技术的核心是在玻璃基板上制造贯穿通孔,实现芯片之间的高效互连。相较于传统的硅通孔(TSV)技术,TGV拥有显著的优势。首先,玻璃材料作为绝缘体,能够有效减少衬底损耗和寄生效应,确保信号传输的完整性和可靠性。其次,玻璃热膨胀系数可调,这有助于降低与不同材料间的热失配风险,提高整体系统的稳定性。此外,超薄玻璃衬底的易获取性和无需额外沉积绝缘层的特性,使得TGV技术在工艺流程上更加简便,成本更低,尤其适用于超薄转接板的生产。

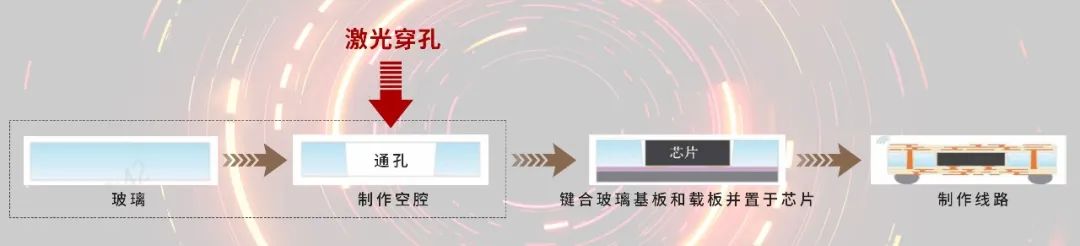

尽管TGV技术前景广阔,但其通孔制备过程面临诸多挑战,需要满足高速、高精度、窄节距、侧壁光滑、垂直度良好及低成本等严格要求。目前,激光诱导刻蚀已成为制备TGV通孔的主要方法。利元亨TGV通孔制备流程利用激光高能量脉冲诱导玻璃产生连续变性区,随后使用湿法腐蚀,从而快速而精确地形成玻璃通孔。

截至目前,利元亨半导体玻璃激光穿孔设备在多个核心性能指标上达到了行业领先水平,为先进封装技术的发展提供了强有力的支持。以下是该设备的关键性能特点:

为了进一步推进TGV技术的研发与应用,利元亨开发了一套先进的半导体玻璃激光穿孔实验平台。该平台集成了多项尖端技术,包括手动上下料系统、行业领先的红外飞秒激光器、贝塞尔光束聚焦系统、真空吸附治具等。平台能够处理100×100mm至360×360mm范围内不同尺寸的玻璃基板,支持厚度从0.1mm到1mm的玻璃材料。在洁净室内进行的工艺验证过程中,实验平台能够有效避免灰尘杂质的引入,确保激光加工区域的清洁度和加工质量。

利元亨半导体玻璃激光穿孔设备凭借其卓越的技术性能和创新的工艺方案,为TGV技术的发展提供了强大的支持,有望在未来电子封装领域发挥重要作用。

Technology as the Foundation | Lyric's Semiconductor Glass Laser Drilling Equipment Drives the Future of Electronic Packaging

With the rapid advancements in cutting-edge technologies such as 5G communication and artificial intelligence, the demand for high-performance electronic products continues to rise, propelling the evolution of advanced packaging technologies. Among these, Through Glass Via (TGV) technology—a groundbreaking innovation in microhole glass substrate fabrication—has demonstrated immense market potential in the modern electronics and semiconductor industries. Particularly in frontier fields such as AI computing packaging, RF (radio frequency), optical communications, and Mini/Micro LED technologies, TGV stands out as a pivotal enabler. Its unique characteristics, including superior high-frequency electrical performance, cost-effectiveness, simplified manufacturing processes, and exceptional mechanical stability, make it a critical pathway toward achieving miniaturized, lightweight, and multifunctional electronic products.

Analysis of TGV Glass Through-Hole Technology

At the core of TGV (Through Glass Via) technology lies the fabrication of through-holes in glass substrates, enabling efficient interconnection between chips. Compared to traditional Through Silicon Via (TSV) technology, TGV offers significant advantages. Firstly, glass, as an insulating material, effectively reduces substrate loss and parasitic effects, ensuring the integrity and reliability of signal transmission. Secondly, the thermal expansion coefficient of glass is adjustable, which helps minimize the risk of thermal mismatches with different materials, thereby enhancing overall system stability. Furthermore, the easy availability of ultra-thin glass substrates and the absence of a need for additional insulating layer deposition make TGV technology simpler in terms of manufacturing processes and more cost-effective. This makes it particularly well-suited for the production of ultra-thin interposers.

Lyric's Key Processes for TGV Through-Hole Fabrication

Despite the promising prospects of TGV technology, the through-hole fabrication process faces numerous challenges, requiring adherence to strict standards such as high speed, high precision, narrow pitch, smooth sidewalls, excellent verticality, and cost efficiency. Currently, laser-induced etching has become the primary method for TGV through-hole production.

Lyric's TGV fabrication process leverages high-energy laser pulses to induce continuous modification zones within the glass, followed by wet etching to rapidly and precisely create glass through-holes. This method ensures both efficiency and accuracy, meeting the demanding requirements of modern electronic packaging technologies.

As of now, Lyric's semiconductor glass laser drilling equipment has reached industry-leading levels across several key performance metrics, providing strong support for the advancement of advanced packaging technologies. Below are the key performance features of this equipment:

Technical Specifications

• Laser Source: Ultrafast laser

• Processing Size: Customizable

• Minimum Hole Diameter: 1.5 μm

• Maximum Aspect Ratio: 1:100

• Positioning Accuracy: < ±2 μm

• Drilling Efficiency: > 5000 points/s

• Glass Thickness: 0.1–1 mm

• Processing Trajectory: Fixed optical path & high-precision motion platform

• Equipment Dimensions: 2220 × 1930 × 2120 mm

• Equipment Weight: < 5.6 tons

Semiconductor Glass Laser Drilling (TGV) Experimental Platform

To further advance the research and application of TGV technology, Lyric has developed an advanced semiconductor glass laser drilling experimental platform. This platform integrates multiple cutting-edge technologies, including a manual loading and unloading system, an industry-leading infrared femtosecond laser, a Bessel beam focusing system, and a vacuum adsorption fixture.

The platform is capable of handling glass substrates of various sizes, ranging from 100×100mm to 360×360mm, and supports glass materials with thicknesses from 0.1mm to 1mm. During process validation in a cleanroom environment, the platform effectively prevents the introduction of dust and impurities, ensuring the cleanliness of the laser processing area and the overall quality of the machining process.

With its outstanding technical performance and innovative process solutions, Lyric's semiconductor glass laser drilling equipment provides robust support for the development of TGV technology. It is poised to play a significant role in the future of electronic packaging.

发表评论